Mechanical Seal Support System Welding: Common Challenges and How Automation Solves Them

Introduction: Why Welds are More Important Than You Think The mechanical seal support systems are the ones that ensure efficient...

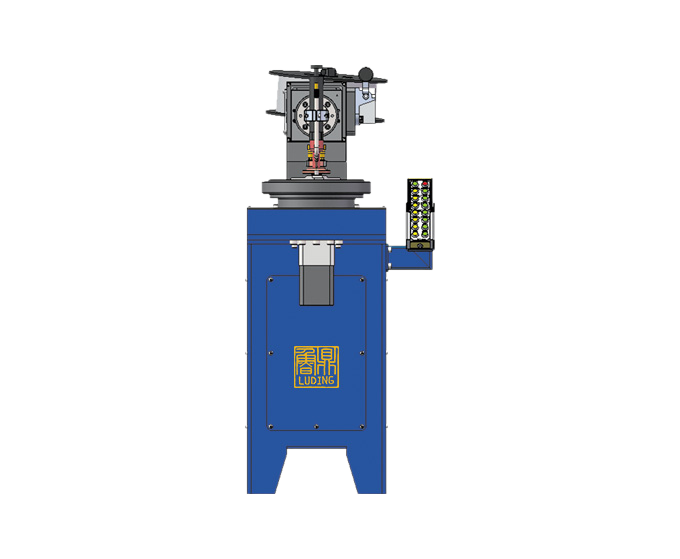

For various short pipe welds on materials like carbon andlow-alloy steel. Ideal for corner and circumferential seams.

No matter the arc starting point, it automatically adjusts the nozzle height in real-time, unaffected by the workpiece's elliptical shape.

Achieves a larger welding area, maintains a constant temperature in the welding zone, and results in better weld formation.

Fully automatic layered welding for thick-walled workpieces, including root pass, fill, and cap, capable of welding up to 8 layers without manual intervention.

20 years of optimization, stable structure, and forced water cooling. Capable of continuous operation for 8000 hours without abnormalities during non-stop testing.

Can store up to 30 sets of circumferential welding and 10 sets of longitudinal welding settings for easy recall based on workpiece specifications.

One-button operation for fully automated welding, featuring automatic wire retracting and pulsed wire feeding. One machine is equivalent to 1.8-2.5 skilled welders.

Single-side welding with double-side formation, welds can be verified through pressure testing and NDT (Non-Destructive Testing).

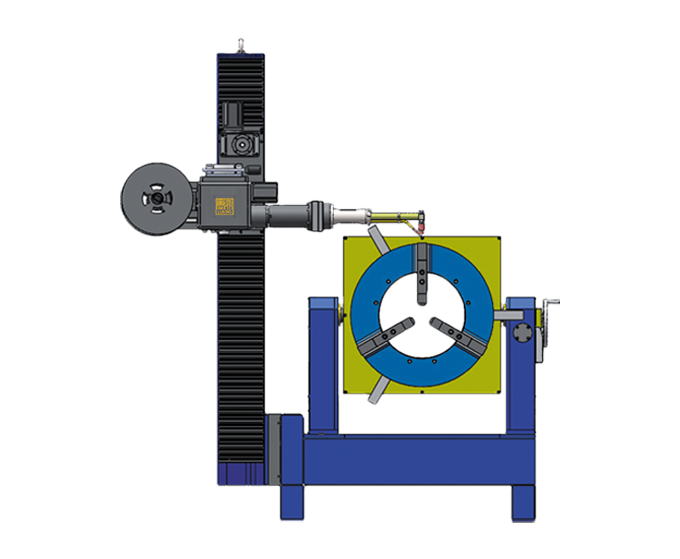

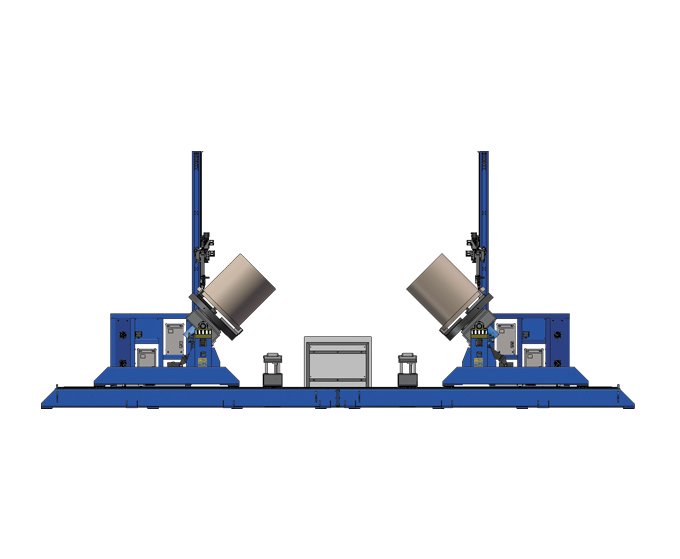

Electric 7-axis robotic arm + full-angle electric positioner, capable of performing circumferential and longitudinal welding at any angle.

Become a world-class provider of automatic welding solutions.

To set the benchmark for excellence in automated welding, delivering precision and reliability that exceed expectations.

Customer-centric, driven by dedicatedindividuals, united and efficient, withsincere passion.

Welding Automation Solutions by Mecanext are specialized in handling circular fillet welds, butt welds, and straight seams, with no manual intervention required. These solutions enable multi-layer fully automated welding of thick-walled workpieces (root pass + fill pass + cap pass

Yes, we provide detailed video instructions, a comprehensive Standard Operating Procedure (SOP) and user manual, and free online technical support.Typically, these are sufficient.

If needed, we also offer on-site engineer training under relevant fee covered by clients.

For standard models, we typically have machines in stock, and the lead time is around 7 working days after payment is received. For customized solutions, the lead time may vary depending on complexity—please contact us for specific timelines.

We work with reliable, globally recognized welding brand Panasonic for the welding machine and PLC. They are connected via analog signal. All functions such as the welding power source, equipment rotation and movement, and AVC (Arc Voltage Control) are fully integrated through our PLC system. No external relays are required, and everything can be controlled directly from the main interface or via remote control. More reliable and convenience.

We offer a 12-month warranty starting from the date the machine is installed. During this period, we provide free replacement of non-human-damaged parts and lifetime technical support.

Yes, all our interfaces and programming systems are available in English by default.

Our systems primarily use TIG (GTAW) and Hot/Cold Wire TIG welding processes.

Other processes, such as MIG or Plasma, can be integrated depending on the material and welding requirements.

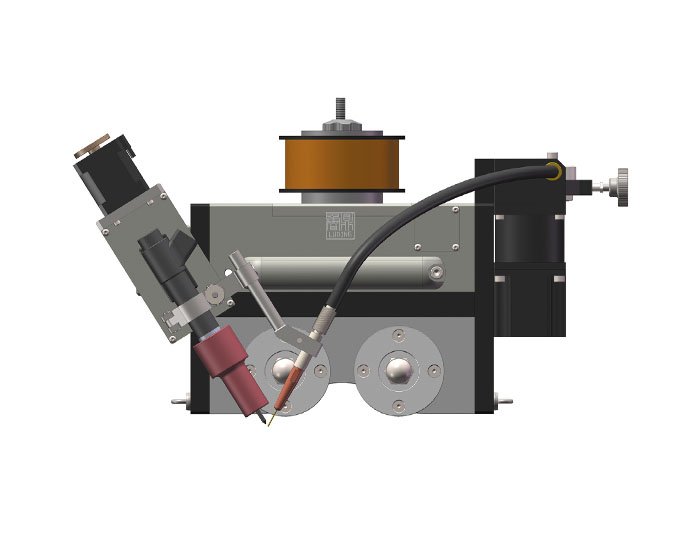

The AVC system automatically adjusts the torch height to maintain a constant distance between the torch and the workpiece.

When welding irregular or uneven surfaces, the torch rises or lowers in real time, ensuring stable arc length and consistent weld quality.

The desired arc length can be precisely set using the remote control, and the system will store and repeat this setting throughout the welding process for uniform results.

Weaving amplitude can be set to accommodate different weld widths. Torch dwell time and weave speed can be independently programmed for each zone, enabling full simulation of welder movement.

Yes, we have implemented pre-purge and post-purge cycles via PLC programming. These functions automatically activate with each welding cycle.

A crater fill (arc extension) function is also available to improve the final appearance of the weld bead.

Wire feed speed is adjustable and supports pulsed feeding in sync with pulse welding. Wire diameter options are 0.8 mm and 1.0 mm.

Yes, we can integrate an internal backing gas purge system to ensure proper shielding inside the bore of hoses, tubes, or closed components during welding.

This feature is especially useful for applications requiring clean, oxidation-free welds on the inner surface.

The torch swing angle is electrically adjustable within a range of ±45°.

It supports electric adjustment on the Y and Z axes, and manual or optional electric adjustment on the X axis.

Together with the rotating chuck, the system enables torch positioning at virtually any angle, including a fully horizontal centerline, to accommodate complex welding geometries.

Introduction: Why Welds are More Important Than You Think The mechanical seal support systems are the ones that ensure efficient...

Introduction: Operating with High Risks in Metal Hose Welding Selecting the right automatic welding machine for your auto metal hose...

Orbital welding is a welding process that is carried out by a orbital welding head, and it is also known...

We Are Committed to Delivering Quality Welding Solutions.

Empowering industries worldwide with precision, efficiency, and advanced welding technologies.

Jigao Innovation and Entrepreneurship Industrial Center, 803 Keyuan Road, High-Tech Zone, Jinan, Shandong Province